ठà¤à¤¾à¤°à¥à¤¬à¤¨à¤¿à¤ रसायन सà¥à¤ªà¥à¤°à¥ डà¥à¤°à¤¾à¤à¤¿à¤à¤ à¤à¥à¤¬ वरà¥à¤à¥à¤¸

ठà¤à¤¾à¤°à¥à¤¬à¤¨à¤¿à¤ रसायन सà¥à¤ªà¥à¤°à¥ डà¥à¤°à¤¾à¤à¤¿à¤à¤ à¤à¥à¤¬ वरà¥à¤à¥à¤¸ Specification

- विषैला

- गंध

- भौतिक रूप

- प्रॉडक्ट टाइप

- स्प्रे सुखाने का कार्य

- स्वाद

- शेल्फ लाइफ

- 12-24 months (varies with material and packaging)

- प्रॉपर्टीज़

- Free flowing, fine particle size, uniform distribution

- एच एस कोड

- 2833

- पीएच लेवल

- Typically neutral (can be customized with job work)

- शेप

- दिखावट

- White or off-white powder

- ग्रेड

- औद्योगिक

- उपयोग

- For customers requiring spray drying of inorganic chemicals as a contract job work

- स्टोरेज

- एप्लीकेशन

- घुलनशीलता

- Water Soluble (for most inorganic chemicals)

- पवित्रता

- Customizable (as per process specification)

- घनत्व

- ग्राम प्रति घन सेंटीमीटर (g/cm3)

- सामग्रियां

- Inorganic chemicals (as per client requirement)

ठà¤à¤¾à¤°à¥à¤¬à¤¨à¤¿à¤ रसायन सà¥à¤ªà¥à¤°à¥ डà¥à¤°à¤¾à¤à¤¿à¤à¤ à¤à¥à¤¬ वरà¥à¤à¥à¤¸ Trade Information

- Minimum Order Quantity

- 10000 Kilograms

- आपूर्ति की क्षमता

- 100000 प्रति महीने

- डिलीवरी का समय

- 1 हफ़्ता

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About ठà¤à¤¾à¤°à¥à¤¬à¤¨à¤¿à¤ रसायन सà¥à¤ªà¥à¤°à¥ डà¥à¤°à¤¾à¤à¤¿à¤à¤ à¤à¥à¤¬ वरà¥à¤à¥à¤¸

Offering top-tier Inorganic Chemicals Spray Drying Job Works, this solution guarantees exceptional particle size control, uniformity, and purity. Ideal for various industries, including pharmaceuticals, agriculture, and materials science, the process ensures high efficiency and consistency. With state-of-the-art equipment and precise formulations, every batch meets stringent quality standards. Enjoy the benefits of reduced moisture content, extended shelf life, and enhanced product stability. Trust in this expertise for reliable, high-quality Inorganic Chemicals Spray Drying Job Works tailored to your specific needs.

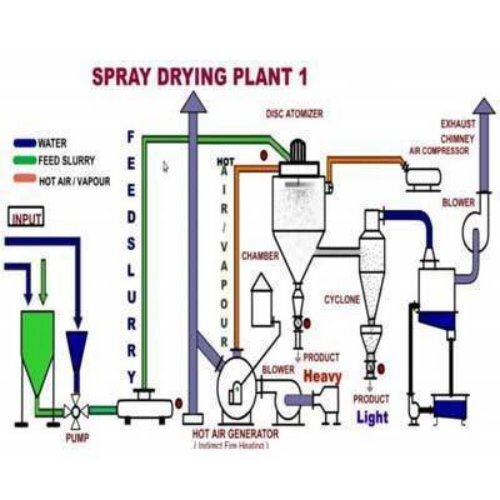

Precision Spray Drying Technology

Employing hot air spray drying with rotary atomizer and pressure nozzle systems, our process ensures uniform, free-flowing powders tailored to your specifications. Particle size, moisture content, and temperature profiles are precisely controlled, resulting in spherical or amorphous, tasteless and odorless powdersideal for industrial applications demanding high performance.

Extensive Customization and Service

We offer comprehensive customization, allowing clients to adjust process parameters, choose packaging options, and specify product purity and physical form. Whether you need HDPE bags, paper bags, or drums, our packaging is designed to preserve product integrity and extend shelf life according to material needs.

Assured Quality and Compliance

All operations strictly adhere to industrial safety and quality standards. Our technical support team is available for consultation throughout the job work process, and sample batches can be provided on request, ensuring client confidence and satisfaction.

FAQs of Inorganic Chemicals Spray Drying Job Works:

Q: How does the spray drying process work for inorganic chemicals?

A: We utilize hot air spray drying technology, where inorganic chemical solutions or slurries are atomized using rotary atomizers or pressure nozzles. These droplets are rapidly dried in controlled temperature ranges (120C250C), resulting in fine, free-flowing powder with customizable particle size and moisture content.Q: What types of inorganic chemicals can be processed through your job work service?

A: Our facilities are equipped to handle a broad spectrum of inorganic chemicals as specified by clientsincluding industrial raw materials, catalyst carriers, pigments, ceramic intermediates, water treatment compounds, and fertilizers. Purity and formulation are tailored to individual requirements.Q: When should samples be requested and how are they provided?

A: Samples can be requested prior to full-scale production to validate process outcomes and product quality. Upon request, we prepare and ship sample batches according to your specified parameters for assessment.Q: Where is your service available and how is job work executed on-site?

A: Our spray drying job work service is available Pan India. Job execution is carried out offline at our manufacturing sites, with clients able to coordinate directly for batch processing, technical consultations, and sample analysis.Q: What are the key benefits of choosing your contract spray drying services?

A: Clients benefit from customizable process controls (particle size, purity, moisture, temperature), flexible packaging choices, professional technical support, quality compliance, and the ability to process up to 2000 kg per day. Our solutions are designed to maximize reliability, efficiency, and product performance.Q: How can the spray dried powders be used and stored?

A: Spray dried inorganic powders are suitable for applications in catalyst carriers, ceramics, pigments, water treatment, fertilizers, and industrial processes. Products should be stored in cool, dry, well-sealed containers to maintain shelf life, typically ranging from 12 to 24 months.Q: Is there a minimum order quantity for spray drying job work?

A: Our standard minimum order quantity is 250 kg, but this can be negotiated based on project scope, chemical type, and client requirements.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email